Miller acknowledges that shifting work towards automated factories could threaten jobs, but argues that more efficient manufacturing plants will create better jobs for displaced workers. On average, each facility employs about 130 people – the average Nike-making factory in China has about 1,300 – and they specialize in things like high-tech air bubbles, not finished shoes. There are already 49 factories making Nike products here. are pushing their own advanced manufacturing efforts with similar goals in mind.Īutomation factors heavily into Nike’s plan to move factories closer to the U.S. Grabit, said Nike’s Chief Operating Officer Eric Sprunk in an email, “strategically fits with Nike’s drive to accelerate advanced manufacturing.” Major Nike competitors like Adidas AG and Under Armour Inc. Nike runs a skunkworks for advanced manufacturing in Oregon, and in 2015 announced a partnership with Flex, one of its manufacturing partners, to develop new tech. It would like to move operations closer to big consumer markets in Europe and the U.S. There are just over a million people who make Nikes in 591 factories worldwide, according to the company, with production tilted heavily toward the cheap labor markets in Asia. Over the course of an eight-hour shift, a machine monitored by a single employee can make from 300 to 600 pairs of shoes.

It can take a human worker 10 to 20 minutes to arrange the pieces of the upper Grabit’s machine does it in 50 to 75 seconds.

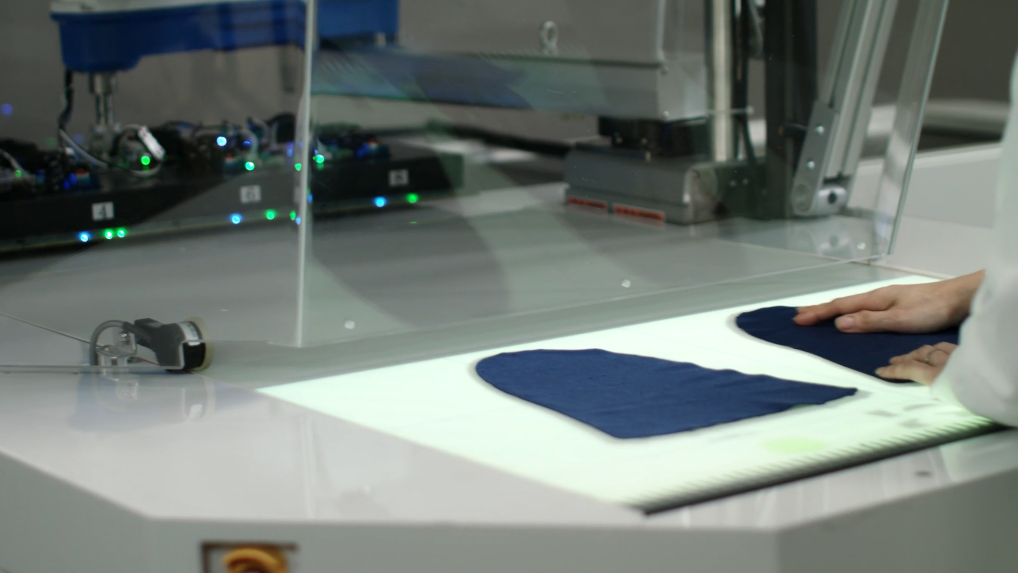

The machine moves over to a partially finished shoe and turns the electric charge off, dropping them into the right configuration and feeding them into a heat press. A platform covered in electroadhesive pads descends to pick everything up, while cameras monitor the progress.

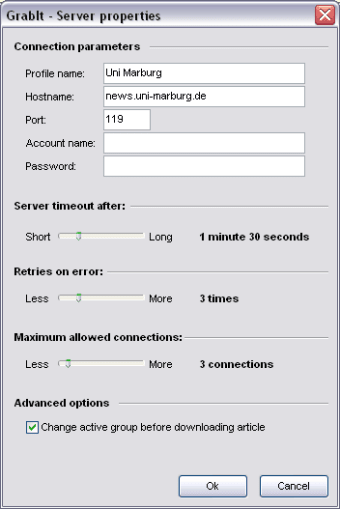

GPM GRABIT SOFTWARE

Software decides the best way to stack pieces of the upper, then lights up portions of a glass table, showing its human partner where to set things down. They’re also designed to work with flesh-and-bone human employees. The Grabit machines in shoe factories look more like oversized panini presses than electronic humanoids. Prahlad spun Grabit out of SRI 2013, and the company raised about $25 million from investors that include the electronics maker Flex, and Esquel, a garment manufacturer, and Samsung. He spent some time building wall-climbing robots before deciding that the real opportunity was in manufacturing and logistics. Harsha Prahlad, who founded the company and now serves as its chief technology and products officer, holds about three-dozen patents related to electroadhesion. The concept for Grabit was hatched at SRI, a prominent nonprofit research institute in Menlo Park, California. “The things we’re getting pulled into, we’re getting pulled into because they can’t be done another way,” he said. This makes Grabit able to do things robot-hand companies are unlikely ever to conquer, says Greg Miller, Grabit’s chief executive officer. Instead, the company implements flat pads of electrodes that, when charged correctly, create an electric field that adheres to nearly any surface. For Grabit, the partnership with Nike shows its work is catching the eye of the world’s more prominent apparel companies.ĭespite its name, Grabit’s innovation isn’t based on having robots mimic the human-style grabbing motion. Robotic arms have been doing much of the labor in car factories for years, and Amazon sponsors an annual contest to get academics to make robots smart enough to pick up objects they’ve never seen before. Pretty much every company that makes physical objects is interested in automation. This could be a step forward in Nike’s attempt to change the economics of shoemaking so it can relocate manufacturing closer to the big consumer markets in the U.S. By the end of the year, about a dozen of these machines will be operating in China and Mexico. In the past month, Grabit has begun providing facilities that make Nikes with a handful of upper-assembling machines that can work at 20 times the pace of human workers. More recently, Nike has quietly become one of the startup’s first customers. made an investment in a startup based in Sunnyvale, California called Grabit that uses electroadhesion - the type of static electricity that makes your hair stand up when you rub it against a balloon - to help machines manipulate objects in novel ways.

0 kommentar(er)

0 kommentar(er)